Fragile weigher

Fragility combined with speed and accuracy

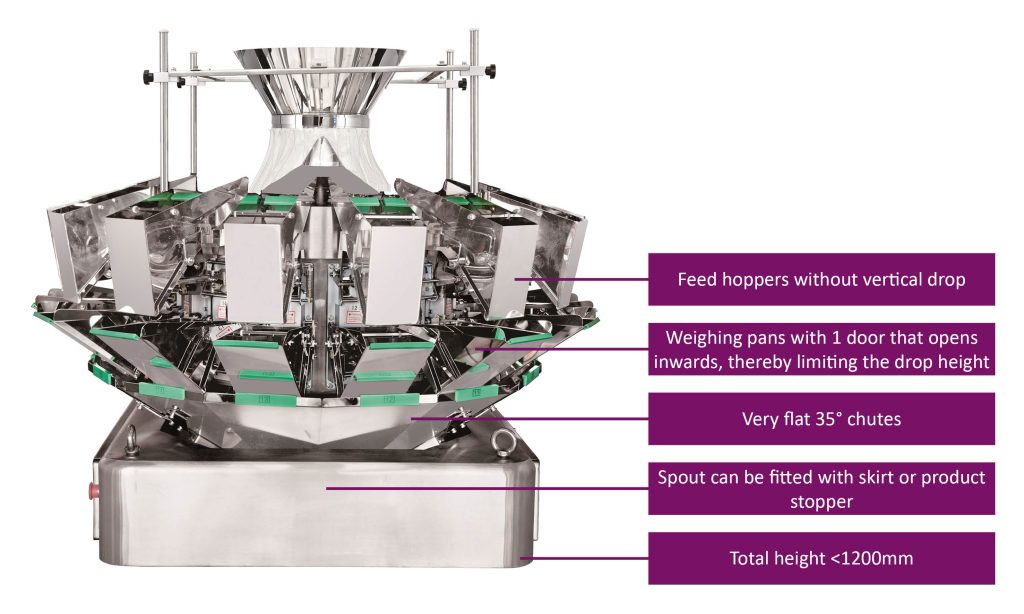

The fragile weigher has been specially developed in response to the demand for weighing fragile products such as biscuits and cookies with as little damage as possible. Every multihead weigher has drop heights, which is not a problem for many products, but in some cases simply causes too much breakage. In the fragile weigher, all these drop distances have been minimised or replaced by a sliding movement.

For example, the feed and weighing hoppers are not placed vertically above each other, but are designed in such a way that a sliding movement is created from the vibrating chute. As soon as the storage hopper opens, the product lands in the weighing hopper again via a sliding movement. This significantly reduces breakage compared to a conventional multihead.

Once the optimal combination of weighing hoppers has been determined, they are discharged via the slide chutes to the packaging machine. These slide chutes are very flat at 35°, so that not much falling speed is built up, which again limits breakage. Optionally, a skirt or product stopper can also be provided at the outlet of the weigher to reduce the impact of products colliding with each other.

With a maximum speed of 50 (10-head) to 90 (14-head) weighings per minute, there is no limitation on the speed and excellent accuracy of Combimat. As standard, it is possible to open the selected weighing hoppers in quick succession. This creates a longer string of product, which falls more easily through the feed hopper of the packaging machine if a narrow bag size is selected.

In addition, all contact parts of the machine are easy to dismantle for cleaning, which guarantees maximum uptime of the weigher.