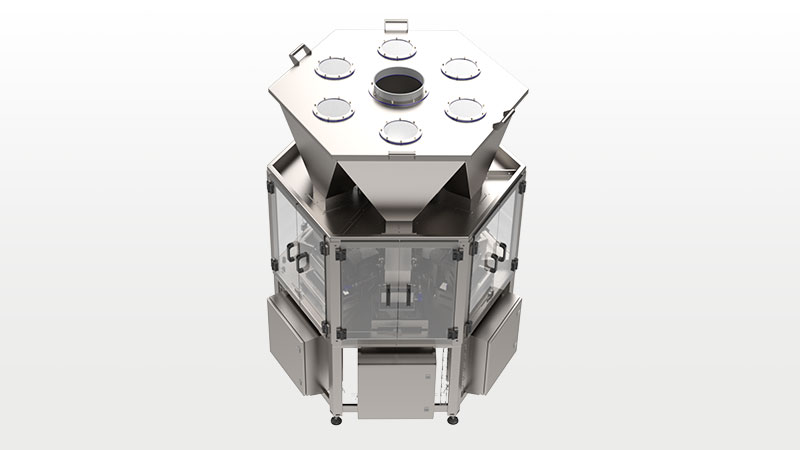

NewWeigh FreeFlow

The NewWeigh FreeFlow weighers have been specially developed for free-flowing goods. Because no vibrating chutes are used, there is very little dust generation and the footprint is extremely small. Optimal accuracy can be achieved with the servo-controlled dosing slide at the outlet of the hopper.

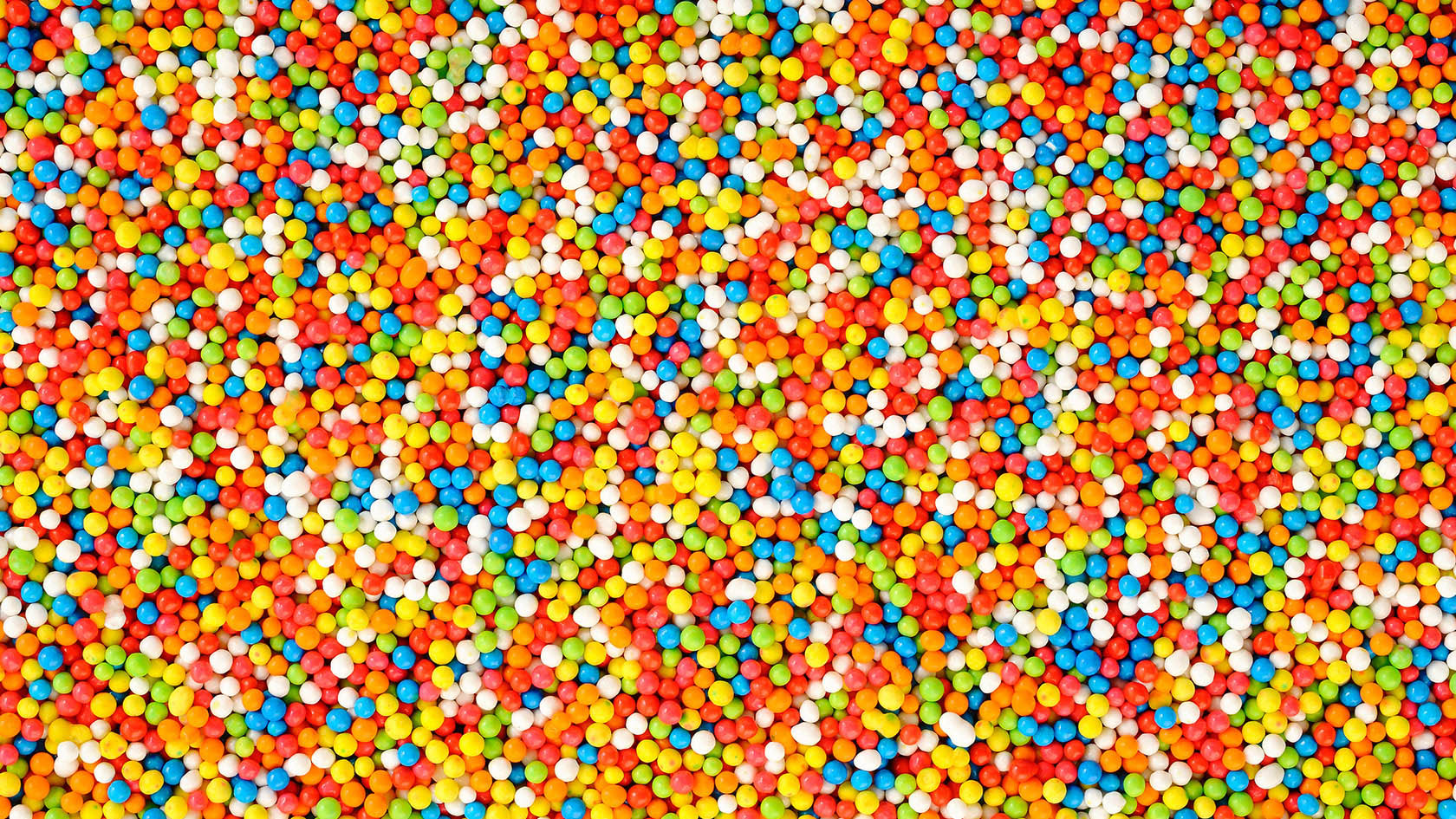

FREEFLOW APPLICATIONS

To be suitable for the FreeFlow, the product must flow naturally under gravity. This makes this weigher suitable for:

HOW THE FREEFLOW WORKS

The heart of the FreeFlow weigher is the servo-controlled product slide. This is positioned between the hopper and the weighing tray to regulate the product flow in the coarse and fine phases with great precision. As no vibrating chutes are used, dust formation and segregation are kept to a minimum. The weigher is also equipped with an enclosure so that a dust extraction system can be installed.

DESIGN

The NewWeigh FreeFlow is made entirely of 304 stainless steel and is also available in 316 stainless steel. The flow of the product can be further optimised by means of surface treatment (e.g. with Teflon) and the creation of an air flow. The servo motor is available in an ATEX version if required. The FreeFlow can be equipped with 1, 2, 3, 4 or 6 heads, for speeds of up to 80 weighings per minute.

CONTROL

NewWeigh weighing machines are equipped with a high-quality IPC control system with:

- User-friendly touch screen control panel in various languages

- Storage of 99 programmes, allowing for quick product changes

- MID approval, making them calibratable

- FTP server for storing all individual weights that can be read remotely